GE, Fraunhofer, voxeljet to develop world’s largest sand binder jetting 3D printer

By DE staff

Additive Manufacturing EnergyProject to accelerate and optimize production of GE’s Haliade-X offshore turbines.

G

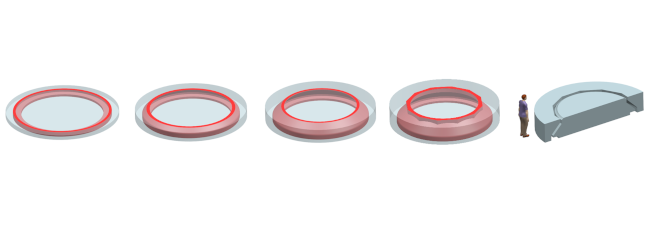

The ACC printer will be designed to print molds for key components of wind turbines, with sizes up 9.5 meters in diameter and 30 to 60 tons in weight.

(Photo credit: VoxelJet)

The project involves the development of a large format 3D printer capable of producing sand molds for casting the complex metal parts that make up an offshore wind turbine nacelle. The modular 3D printing process, which is based on voxeljet’s core “Binder-Jetting” technology, can be configured to print molds for castings up to 9.5 meters in diameter and 60-plus tons in weight. The Fraunhofer Institute for Casting, Composite and Processing Technology IGCV will be responsible for casting and materials technology issues as well as digital process monitoring.

Currently under development, the Advance Casting Cell (ACC) 3D printer will be capable of printing molds to cast components for the nacelle of the GE Haliade-X that can each weigh more than 60 metric tons. According to the partners, the ACC printer will reduce the time it takes to produce this pattern and mold from ten weeks or more to just two weeks.

In addition, the use of the 3D printer is expected to reduce the product’s carbon footprint by eliminating the need to transport the large parts from a central manufacturing location. The partners expect to launch the project during the third quarter of 2021 with initial printer trials starting during the first quarter of 2022.

“The 3D printed molds will bring many benefits including improved casting quality through improved surface finish, part accuracy and consistency,” said GE senior additive design engineer, Juan Pablo Cilia. “Furthermore, sand binder jet molds or additive molds provide cost savings by reducing machining time and other material costs due to optimized design. This unprecedented production technology will be a game changer for production efficiency allowing localized manufacturing in high cost countries, a key benefit for our customers looking to maximize the local economic development benefits of offshore wind.”

According to the International Energy Agency, global offshore wind capacity will increase 15-fold by 2040, becoming a 1 trillion dollar industry, thanks to falling costs, supportive government policies and technological progress. GE Renewable Energy has been selected to supply its Haliade-X turbine for 5.7 GW worth of projects in Europe and the US.

www.ge.com

www.voxeljet.com

www.igcv.fraunhofer.de